Improve Performance and Cut Costs with Custom BLDC Motors [White Paper]

In our latest white paper, we take a deep dive into custom brushless DC (BLDC) motors. Although engineers often turn to off-the-shelf units, custom motors have many benefits. For example, they can be designed to fit in tight spaces or handle demanding thermal, corrosive or electromagnetic operating conditions. And best of all, custom motor assemblies often reduce the number of components on your bill of materials—lowering your costs and assembly time.

We also take a look at several real-world examples of what’s possible, including:

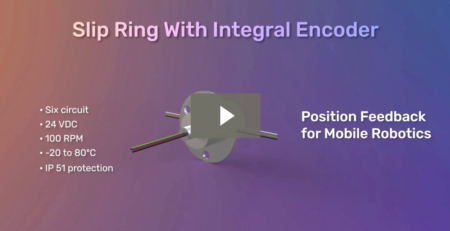

Two Custom Motors for Automated Guide Vehicles. In the first motor, we incorporated a 2-kilowatt, 120-millimeter frame motor with integral brake and encoder, as well as an optional wheel and tire. This arrangement saved space and cost and also increased driveline stiffness. The second unit—based on a 1-kilowatt, 80-millimeter frame motor—achieved high radial load capabilities for carts with 2,000-pound payloads.

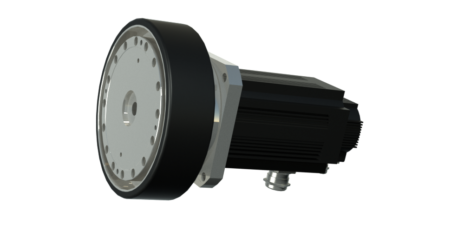

Through-Hole Table and Motor Configuration. This custom motor integrated our THT Series of through-hole tables to create a complete actuation solution for an inspection process. Our THT Series combines the advantages of servo motors, cam dividers and direct drive motors to provide high precision and rigidity at a fraction of the cost of similar direct-drive tables.

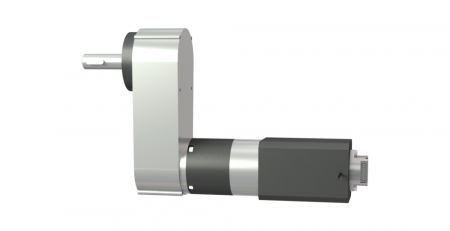

BLDC Motor with Integral Planetary Gear Reducer. This custom motor included an integral planetary gear reducer for a motion control application. By optimizing this motor’s design to meet various speed, voltage and mounting requirements, we successfully supplied a high-quality assembly that improved motor controllability and saved cost.

To learn more about the benefits of custom BLDC motors, download our latest white paper.