Choose Slip Rings That Stand up to Harsh Conditions

Slip rings often deploy in challenging environments that can affect their reliability and operating life. However, some slip rings withstand harsh operating conditions better than others. In order to choose an appropriate slip ring for its intended operating environment, be sure to keep the following challenges in mind:

- Corrosion. Food processing and medical equipment undergo frequent cleanings or sterilizations, while marine cable turbines and wind turbines located at sea will be exposed to saltwater and spray. In each of these environments, rust must be prevented.

- Shock and vibration that can occur in heavy industrial and downhole environments.

- Wear caused by contact forces in demanding applications.

- Harsh temperatures such as those found in remote, outdoor environments.

- Service life. Long service life can be a critical selection factor. You want your slip ring to last in harsh environments and reduce service calls — especially to difficult-to-reach places like downhole or in wind turbines.

Look For IP65-rated Slip Rings

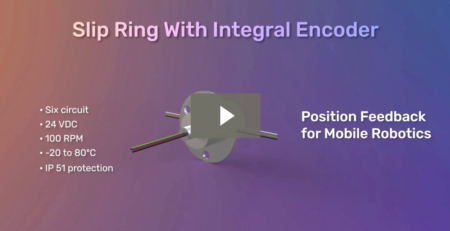

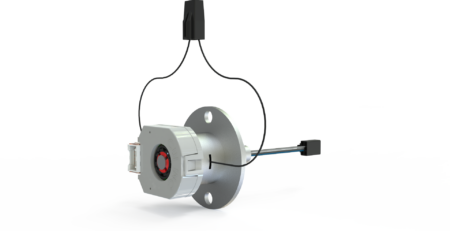

If you expect your design to be deployed in a harsh environment, look for a slip ring with an IP65 rating. IP65 indicates a product resists both dust incursions and water when splashed or exposed to low pressure washdown. Orbex now offers slip rings that carry IP65 ratings and can withstand dust and moisture as well as other demanding industrial and environmental conditions. Orbex IP65-rated slip ring series include:

- 200 Series harsh environment slip rings. These slip rings are made from stainless steel to resist shock, vibration and corrosion in salty or washdown environments, and they can operate over a wide temperature range of -40 to 80°C, with some models available up to +85°C. Orbex’s innovative channeled brush technology creates multiple contact points and reduces contact forces to minimize wear in demanding applications. And with up to 80 million revolutions, the 200 Series provides exceptionally long service life.

- 300 Series miniature slip rings (with the “F” option). Suitable for use in compact spaces, 300 Series miniature slip rings feature a small rotor diameter that minimizes surface speeds and imbalances to extend the ring’s service life.

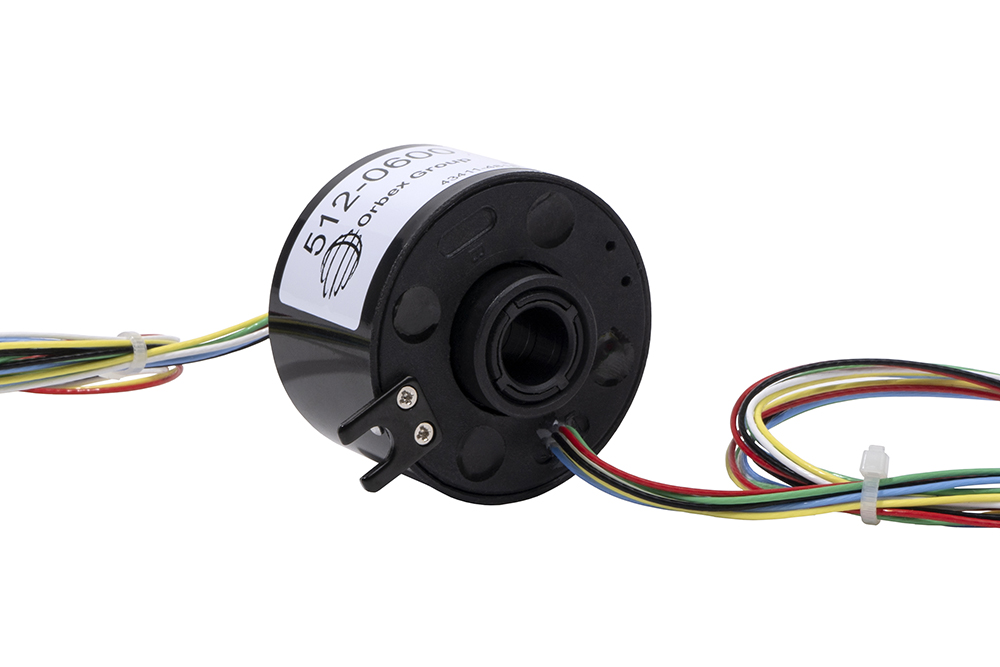

- 500 Series through bore slip rings. (with the “F” option)These compact slip rings are appropriate for applications where a through hole is required. The 500 Series requires little maintenance and incorporates Orbex’s advanced channeled brush technology to increase service life.

Standard or Custom IP65-rated Slip Rings Address Tough Conditions

Orbex offers standard versions of these rugged IP65-rated slip rings, and we can also ship made-to-order units to suit special requirements like custom cables and connectors, special temperature ranges or particular power and signal circuit counts and mixes. In fact, Orbex makes it easy to configure your slip ring with our online tool so you’ll receive exactly the product you need given its application and operating environment. Simply select the form factor you need and enter your required power, signal and data circuit criteria, plus dynamic requirements like speed, duty cycle, temperature range and your desired lifetime. We’ll use this information to deliver the slip ring units you need when you need them.

Be sure to compare your harsh environment needs and design requirements with Orbex IP65-rated slip rings to find a standard or custom unit that will give you peace of mind.

Select or configure your Orbex IP65-rated slip rings.