Step Up From Stepper Motors With Brushless DC Motors

Thanks to their high torque and compact size, brushless (BLDC) motors are becoming a popular choice for today’s dynamic servo applications. In many ways, these motors are a “step up” from stepper motors—improving the performance of your servo machines, lowering your maintenance needs and reducing costs.

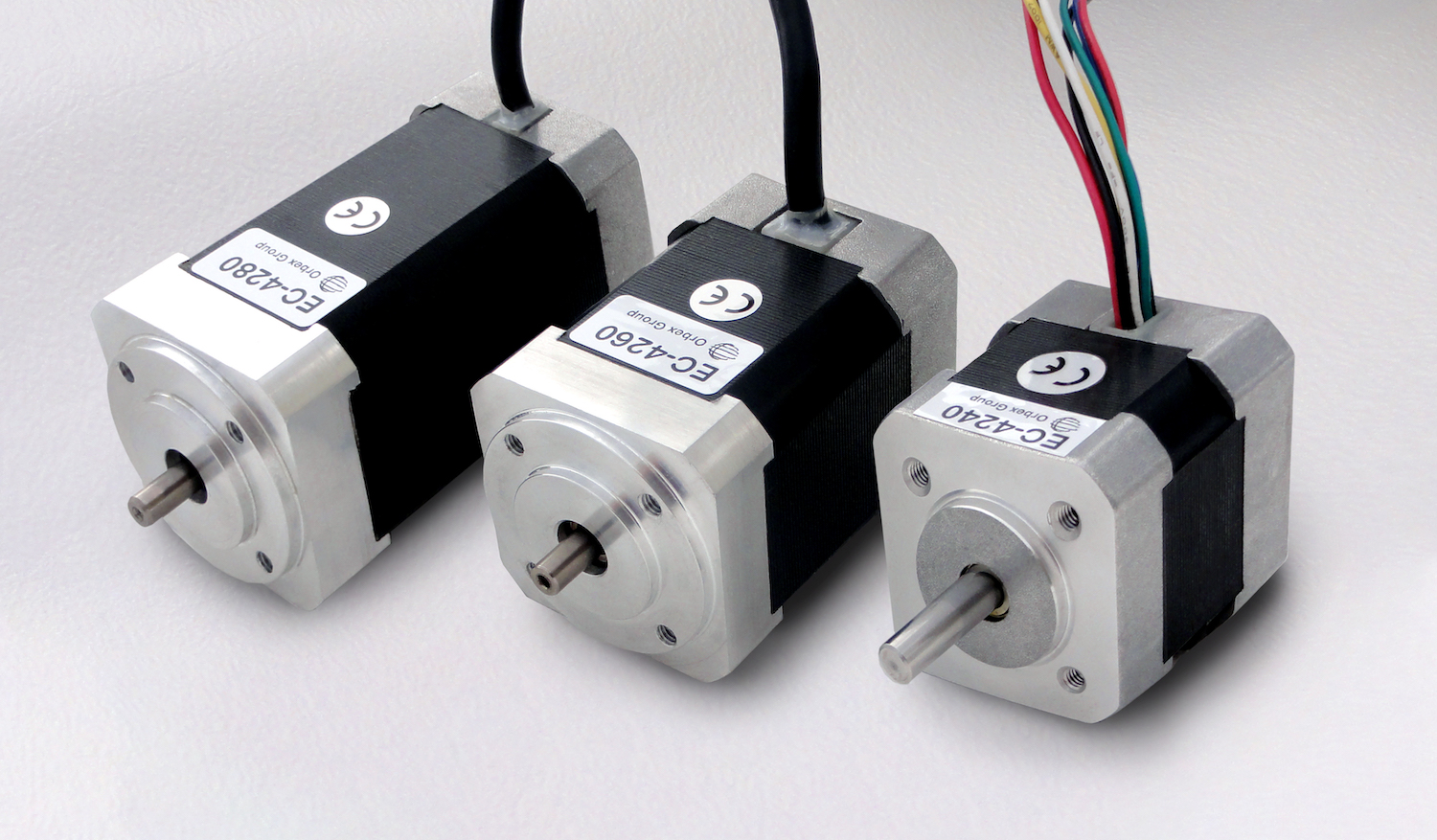

At Orbex, our powerful, yet cost-effective EC family of BLDC motors unlocks a range of benefits in applications that previously relied on stepper motors. Let’s take a closer look at these benefits:

BLDC Versus Stepper Motors

While stepper motors have their place—for example, in applications that don’t require advanced position control, high shaft speeds or space savings—BLDC motors are the way to go in more demanding applications.

These motors pack a lot of torque in a compact package and feature high power output—roughly three times that of equivalent stepper motors. This difference is due to the high number of poles stepper motors need to achieve precise position control and inefficient open loop control techniques.

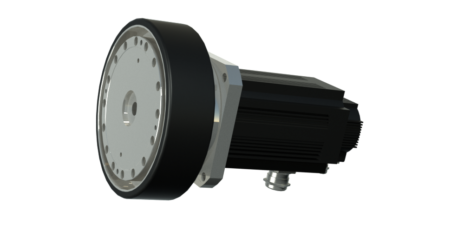

BLDC motors, on the other hand, achieve precision without the tradeoff in rotational speed or torque. They operate at higher speeds and are ideal for applications requiring closed-loop control—from robotic arms to packaging machines.

Orbex Cost-Effective BLDC Motors

While the benefits of BLDC motors are clear, their higher cost may have deterred you from stepping up your motor game. Fortunately, Orbex offers powerful, reliable BLDC motors that you can integrate into your servo machine without breaking the bank.

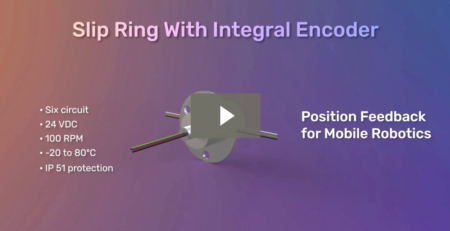

Available in a compact 42-mm frame size, our BLDC motors include incremental encoders for position feedback and hall effect sensors for electrical commutation—enhancing motor efficiency, minimizing maintenance requirements and increasing throughput. They also feature instrument or commercial quality construction and IP51-level protection.

Make It Your Own

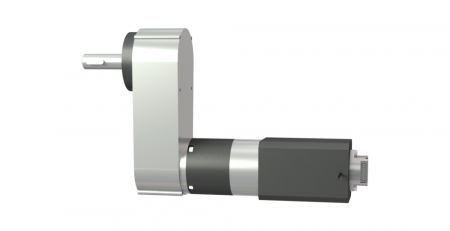

Best of all, you can choose from a variety of customizable features to improve motor efficiency even further, including brakes, connectors, gear reducers, and mounting options. Our BLDC motors even come in frameless options for easy integration into higher-level assemblies.

Other notable features include:

- NdFeB magnets

- Power range: 40–100 W

- 24 and 48 VDC windings

- Optional low cost magnetic encoder

- Optional direct mount to planetary reducer

- IP51 protection

- Low cost <$100

To learn more about our BLDC motors, visit orbexgroup.com/bldc-motors.