Maintenance-free slip rings and high-torque motors for demanding packaging machines

Packaging machines require high cycle speeds and round-the-clock operation to maintain productivity levels. Your slip rings must handle these demands, enabling the reliable transfer of power and electrical signals between your machines and control system—all day, every day.

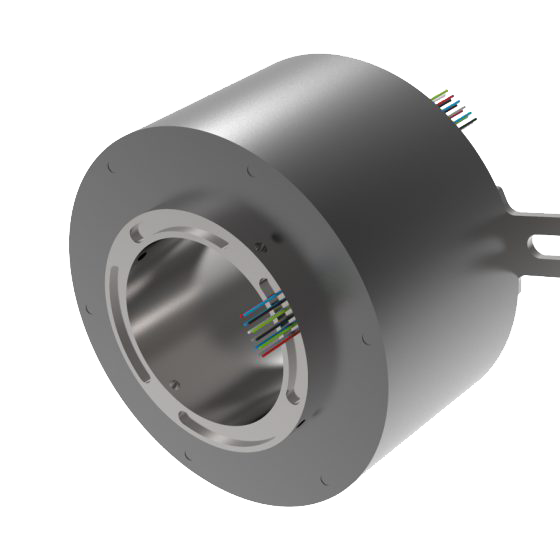

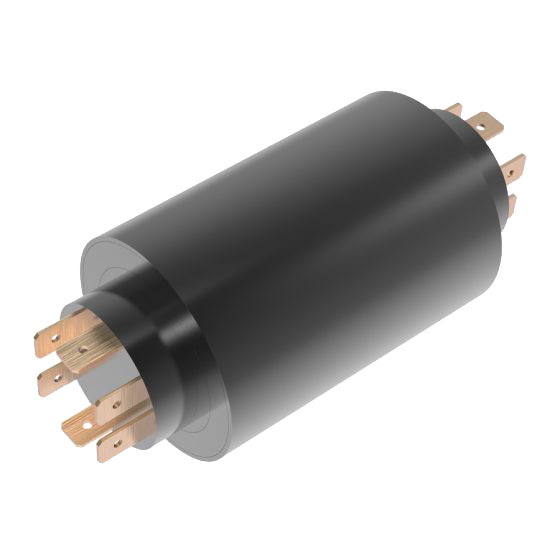

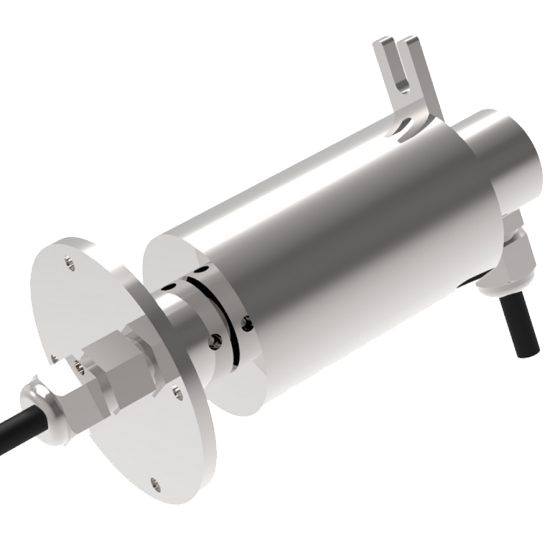

An alternative to mercury-based slip rings, our High Current Slip Rings are ideal for high-current packaging machines that utilize rotary seal bars. They feature a robust yet compact design—achieving long service life in continuously operating machinery.

All slip rings feature our proprietary channeled brush technology, which creates multiple contact points and reduces contact forces—minimizing wear in applications involving high throughput and cycle times. Numerous combinations of power and signal circuits are available to meet your specific requirements.

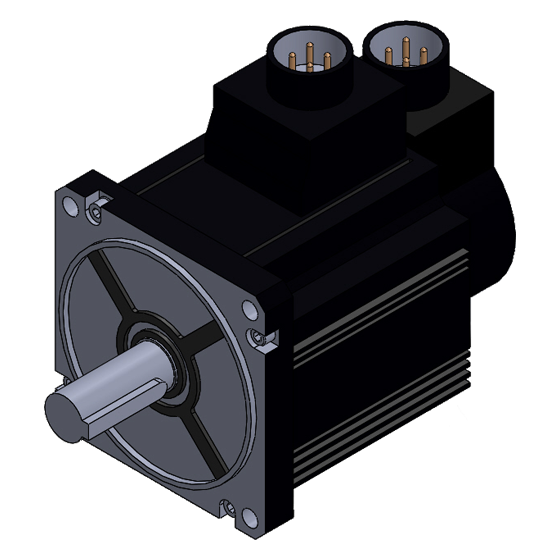

For fast-moving packaging assemblies, our High Performing Brushless Servo Motors combine high torque and smooth motion in a compact, cost-effective package. These motors improve cycle times in a variety of packaging applications—from auger feeders to labeling heads.

Contact us today for more information on how our customized slip ring and motor solutions can benefit your packaging application.

Slip Rings

Advantages

- Mercury-free

- Flexible, modular and compact design

- Long service life

- Maintenance-free

- Current up to 20 A (600 Series)

- Stainless steel housing (200 Series)

- IP65-rated for washdown

- CE and RoHS compliance

- Capable of high-speed data rates for all common field buses

Electric Motors

Featured Product

Advantages

- Customizable

- IP65 protection

- Power range: 50 W–7.5 kW

- Variety of feedback options

- Available with precision planetary gear reducers