Robust slip rings feature long service life in tough oceanic conditions

Marine environments have some of the toughest conditions on earth. Your slip rings must be able to withstand continuous exposure to saltwater, extreme temperatures and high winds—all while reliably transmitting power and electrical signals in large, rotating equipment, including wind turbines, offshore cranes, remotely operated vehicles (ROVs) and more.

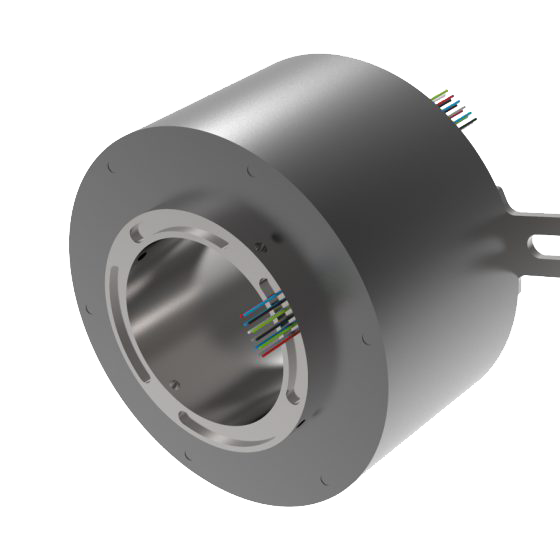

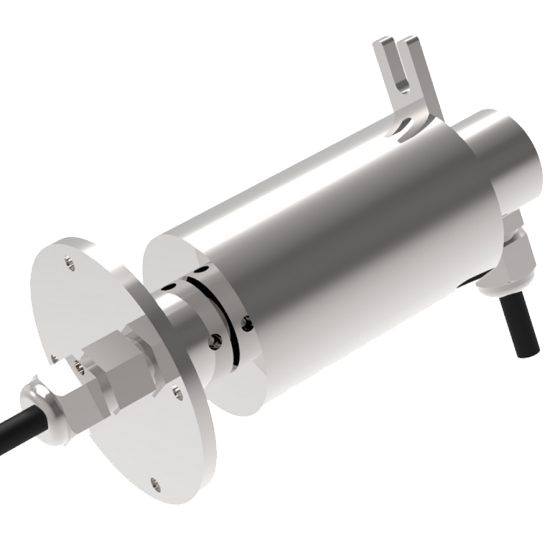

Our Harsh Environment Slip Ring overcomes these challenges. Thanks to its rugged, stainless-steel construction, this IP65-rated series resists corrosion in salty environments, as well as shock and vibration. We can also extend its already wide temperature range (-40° to 80°C) depending on your application.

This series features the longest service life of any of our slip rings—up to 80 million revolutions. It integrates our proprietary channeled brush technology, which creates multiple contact points and reduces contact forces to minimize wear in demanding marine and offshore applications.

Slip rings are easily customizable and feature a unique modular design that enhances installation flexibility and enables numerous combinations of low-current signal and high-current power circuits in the same device.

Contact us today for more information on how our customized slip ring and motor solutions can benefit your marine application.

Slip Rings

Advantages

- Modular configuration with signal and power circuits

- Multiple connector and termination options

- Stainless steel housing

- Long service life

- Extended temperature range

- Resists saltwater, shock and vibration

- IP65 protection

- CE and RoHS compliance