Custom, Connectorized Slip Rings Save Time and Money

When specifying a slip ring, you’ll find many off-the-shelf units to choose from. While standard slip rings meet most application requirements, sometimes you’ll need to customize a slip ring to save installation time. One customization option that machine designers should consider is adding connectors to interface with nearby parts in the system. This blog post will describe the advantages connectorized slip rings offer and the benefits of partnering with a manufacturer that specializes in custom assemblies.

Depending on the application, slip rings may take advantage of a connector joined to the lead wires in order to interface with motors, sensors or other components. Connectors also help simplify installation or replacement. For example, connectors can save time versus hard wiring, so machines get up and running faster with minimal delays for maintenance and replacement — especially important in remote, hard-to-reach machinery. Connectors also create a more efficient, space-saving design.

Orbex can work with you to create a compact, custom slip ring tailored to your application and interface requirements. Our capabilities include providing wire harnesses that incorporate our slip rings. By incorporating both the slip ring and cable assembly, you’ll receive a cost-effective assembly with a fast turnaround. And, we have the ability to build and test the unit to meet the IIPC/WHMA-A-620 standard — an industry benchmark for quality cables and wire harnesses.

Here are some examples of recent custom slip ring designs we created to help customers meet their challenges:

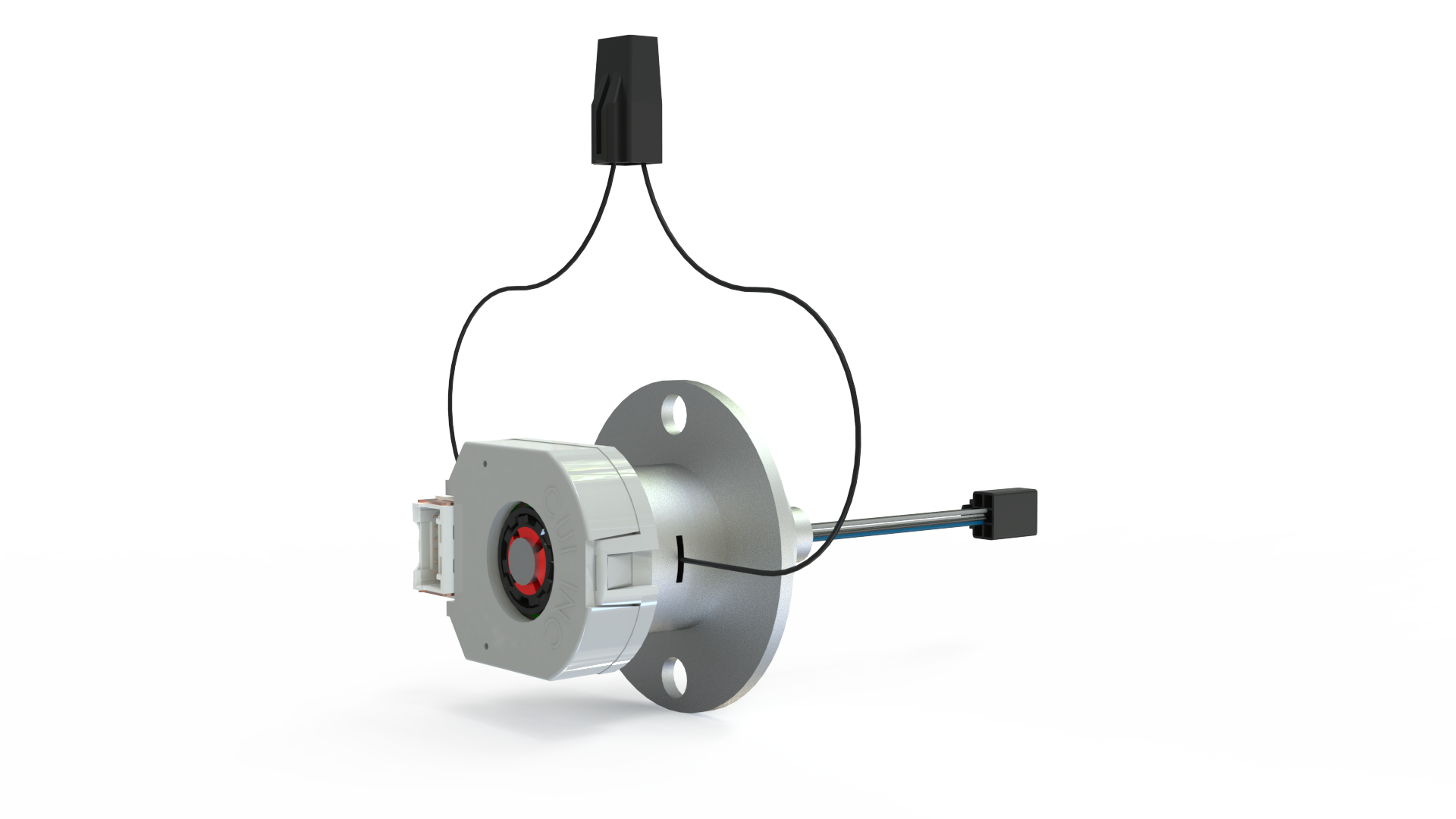

Custom Slip Ring With Bayonet Connector. We custom-designed a 200 Series harsh environment slip ring with a power and signal connector that can deliver a long lifetime in outdoor conditions. The slip ring has a large inner diameter, stainless steel construction and an IP65 ingress protection rating. It was outfitted with customer-specified bayonet style connectors that provided a convenient integration into the customer’s existing wiring. This unit was designed and delivered in eight weeks.

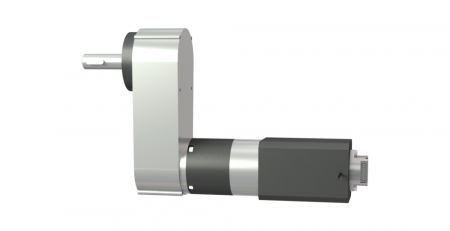

Custom Slip Ring Assembly With Absolute Encoder. A customer recently specified a custom slip ring assembly with an absolute encoder to provide feedback of the output position. We incorporated a custom wire-to-wire signal connector designed for tight spaces along with a wire-to-board mating connector. To ensure high precision, we modified the slip ring with a stainless steel shaft and aluminum housing. In addition, the assembly was calibrated and programmed before shipping.

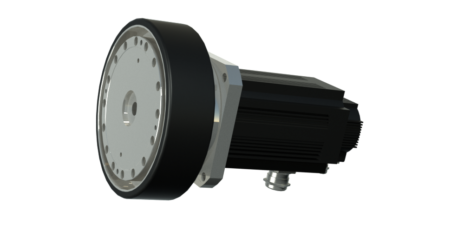

IPC/WHMA-A-620-Compliant Custom Assembly. Orbex can custom-build and test a slip ring assembly to meet IPC/WHMA-A-620. In a recent assembly, we added special cables and signal routing to mitigate high voltage transients. Vertically integrated manufacturing from construction to cable build results in quality, cost-effective solutions.

Custom Slip Ring Assembly for FDA Application. We provided a custom cable length and pin attachments. Thanks to our quality construction, this slip ring assembly is well-suited for an FDA application.

Add Connectors to Your Custom Slip Ring Design in Minutes

Orbex offers an exceptional lineup of standard miniature, hollow shaft, throughbore, high-current and harsh-environment slip rings. Adding connectors to standard slip rings brings the extra benefits of easier installation and less machine downtime, as well as design and cost efficiencies. Check out the video below to see examples of connectorized slip rings, and use our online request form to specify your custom slip ring in just minutes.

To specify your custom slip ring, use our request form.