When to Customize Your BLDC Motors

Engineers often turn to off-the-shelf brushless DC motors (BLDC) motors as stand-alone components to work into their designs. But oftentimes it makes sense to order a custom motor to meet application requirements out of the reach of commodity motors. At Orbex, our application engineering team can work with you on two broad categories of motor customizations:

- To improve size and performance. Commodity motors, by definition, are a “take what you get” proposition when it comes to size and performance. Custom BLDC motors and motor assemblies can be designed to fit in tight or irregular spaces without sacrificing torque density. Motors can also be customized for demanding operating environments — whether the threat is thermal, corrosive or electromagnetic.

- To improve cost. You might think that custom equates to costly. But in many applications, the opposite is true. Custom motor assemblies, for example, allow feature integration that can ultimately take cost out of your products—by reducing the number of components on your BOM and assembly time.

We’ll dig deeper into the advantages of custom motors and show some real-world examples of what’s possible over the next few blog posts.

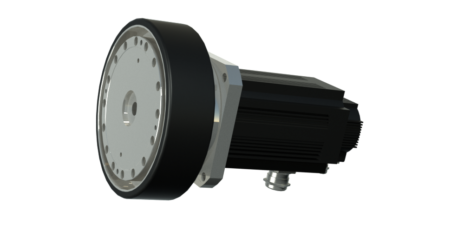

In the meantime, let’s get started with the example of a 42-millimeter BLDC with an incremental encoder, a planetary reducer for the primary reduction and an integrated offset gearbox. Used as an automated guided vehicle (AGV) wheel drive, this motor assembly had to be both compact and powerful — with a 25:1 reduction. This assembly features a direct interface between the motor and gearbox, saving weight, cost and space while maximizing power transmission efficiency. Watch the video below for an overview of the system and check back next month for more examples of custom motor projects.