Custom IP65 Slip Rings Keep the Beer Flowing at a Microbrewery

If you’re running a microbrewery, any equipment downtime can be a macro-size problem for your bottom line. And when it comes to finding a replacement part, it has to withstand harsh, wet conditions and be available as soon as possible. Unfortunately, a replacement slip ring may take months to arrive. Such a lead time is unacceptable for a small-scale business.

Recently, a microbrewery was confronted with this very problem. A slip ring on a bottling machine failed, halting production. When the brewery contacted the OEM bottling machine manufacturer, they were given a 14-week lead time. That’s when they called Orbex Group.

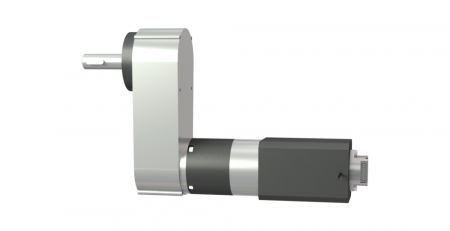

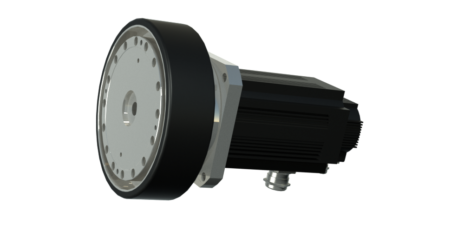

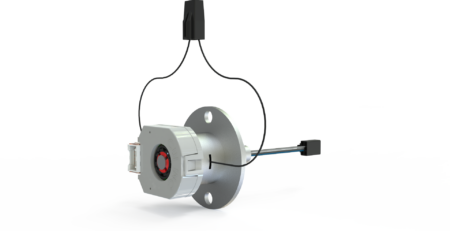

We were able to customize a slip ring that easily integrated into the customer’s assembly. Constructed of food-grade stainless steel, the slip ring carries an IP65 rating and can endure frequent washdowns at the brewery. Because Orbex slip rings are designed with flexibility in mind, our specialists are able to configure the slip ring to exact customer requirements. This particular slip ring was configured for six power signals, four general-purpose I/Os and a DeviceNet field bus network.

This custom replacement arrived at the brewery in just four weeks, allowing the bottles to roll off the production line once again.

Select or configure your Orbex slip rings.