Applications Where BLDC Servo Motors Shine

From packaging to communications, brushless DC (BLDC) servo motors are continuing to gain traction in a variety of industries—and for good reason. By using high-performing magnets and electrical commutation, they reduce rotor inertia in servo applications while achieving high torque, smooth rotation and minimal torque ripple.

In light of these benefits, let’s take a look at some of the applications where BLDC motors really shine:

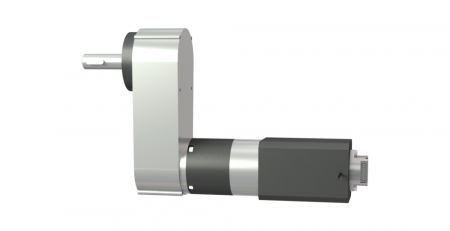

Robotics and AGV. BLDC motors deliver reliable performance across speeds and torque ranges—making them ideal for actuators and continuously rotating joints in robotic manipulators. Because they enable precise control at lower speeds, they’re an especially good fit for surgical robotics systems and other sensitive applications.

Packaging. Because BLDC motors rely on electrical versus mechanical commutation, they include fewer components than their brushed counterparts. Fewer components means less parts will break or require maintenance—improving your uptime in fast-moving packaging assemblies, including auger feeders, labeling heads and palletizing machines.

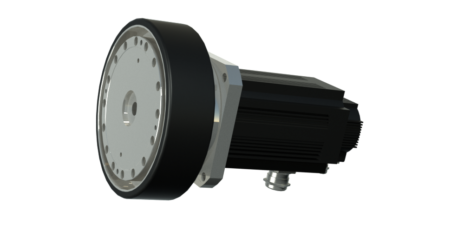

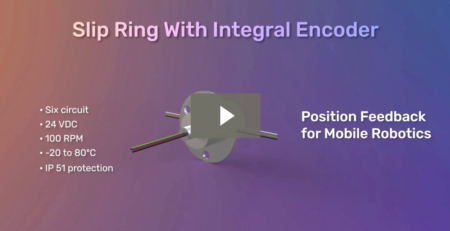

Communications, Security and CCTV. BLDC motors are ideal for antenna pedestals thanks to their high torque and smooth operation. They also play an important role in dome security cameras and other 360-degree systems that run at high speeds. With low cogging torque, these motors prevent camera images from jumping around while scanning. They also include IP51-level protection—further enhancing their reliability in outdoor surveillance applications.

Defense. Due to their low-voltage options, BLDC motors are ideal for unmanned ground vehicles (UGV) and other battery-operated defense equipment. Frameless options facilitate integration into higher-level assemblies while customizable windings further improve motor efficiency in these critical applications.

To learn more about how our BLDC motors can improve your application, visit our motors page.