How Slip Rings Enable Unmanned Aerial System (UAS) Designs

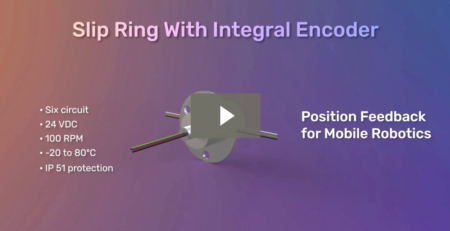

Unmanned aerial systems (UAS), also known as drones and unmanned aerial vehicles (UAV), are becoming ubiquitous in industries like aerospace, defense, agriculture, construction, mining and entertainment. UAS designs feature high-performance components like slip rings to enable their advanced capabilities. Crucial in the design of drones, slip rings provide continuous power, signal and data transmission between stationary and rotary parts.

Slip rings maintain reliable power and control to UAV auxiliary systems — video cameras and sensors — that rotate intermittently or continuously over 360 degrees. Here’s how slip rings support UAS designs.

Cable Management

Cables running to rotating equipment can bend and tangle as they turn, leading to possible cable damage while impacting performance. Slip rings eliminate the potential to twist, tangle and damage cables by enabling reliable power, signal and data transmission over 360 degrees.

Reliable Power, Signal and Data Transmission

A UAV can feature high-resolution cameras and advanced sensor systems for thermal imaging, light detection and ranging (LiDAR), and other environmental sensors. Cameras and sensors are usually mounted on gimbals and other freely-rotating components that allow them to stay on track and on target while the UAS is in flight.

Slip rings are essential to delivering continuous power, data and signal to these components, ensuring their reliable operation and real-time communication. Components like antennas which must maintain connection to ground systems also require uninterrupted power, signal and data transmission.

Increased Efficiency

Drones often have movement and maneuverability requirements, leading to designs that feature compact and lightweight components. Slip rings come in a wide variety of shapes and sizes, and can be designed to fit into the limited installation space available on a UAS while being light enough to contribute minimal weight.

Withstand Harsh Environments

Whether deployed in a disaster response, military reconnaissance or construction application, a UAS has to withstand harsh conditions and stay operational. Because slip rings support UAV auxiliary systems, they are designed to be durable enough to maintain performance in the face of vibrations, temperature extremes, moisture, salinity, dust and debris.

Custom Slip Rings Built for UAS Designs

Although slip rings are well-suited for UAS designs, not all off-the-shelf slip rings will fit application requirements. UAV applications are highly specialized, and forcing a standard product into their design can drive up cost and time in addition to impacting performance. A cost-effective way to ensure optimal performance is to specify a custom slip ring that is designed to meet specifications.

Orbex specializes in delivering custom solutions and our slip rings are no different. We focus on customer requirements to deliver a cost-effective product that is optimized for your application. Our slip rings can be customized with a ride range of options including:

- Special connectors

- Cable lengths

- Extended temperature ranges

- Ethernet or fiber optic communication

- High-speed transmission

- Extended life

Orbex Offerings for UAVs

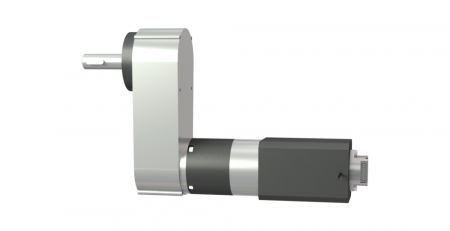

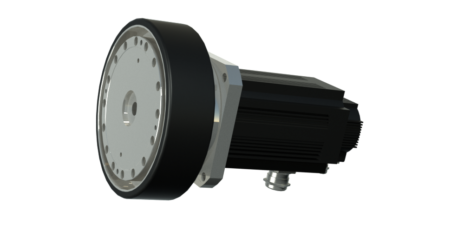

Slip rings aren’t the only Orbex components essential to drone designs. Orbex offers flat brushless DC (BLDC) motors as well as ultra-small pancake-style gimbal motors for UAVs. These motors provide smooth, high-torque and low-cogging motion in a compact package.

Our gimbal motors support the precision required by drone cameras, sensors and antennas, and their small size makes them ideal for keeping drones lightweight. For UAV propellers, we design custom flat BLDC motors to meet specialized performance and durability requirements.

Fill out our form for a custom quote or check out our slip ring or BLDC flat motor product pages for more information.