Custom Slip Rings, Short Lead Times

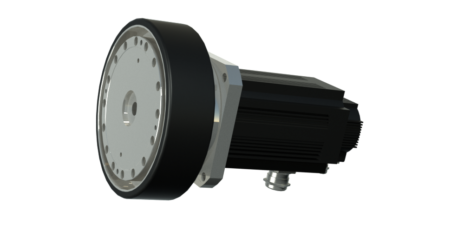

From ship-mounted cranes to pick-and-place robots, we understand how varied the applications for slip rings can be. To help you meet your application requirements, our slip rings feature modular design concepts that make customization quick and easy. And, you get all the benefits of short lead times — only three to four weeks.

Choose from custom cable lengths, wire gauges and connectors, as well as higher IP ratings, alternative housing materials like stainless steel and wider temperature ranges up to 160ºC. We can also increase the number of data channels and increase the size of the through-holes to accommodate space or mounting requirements.

Here are just a few examples of the slip rings we’ve modified over the years to meet unique application requirements:

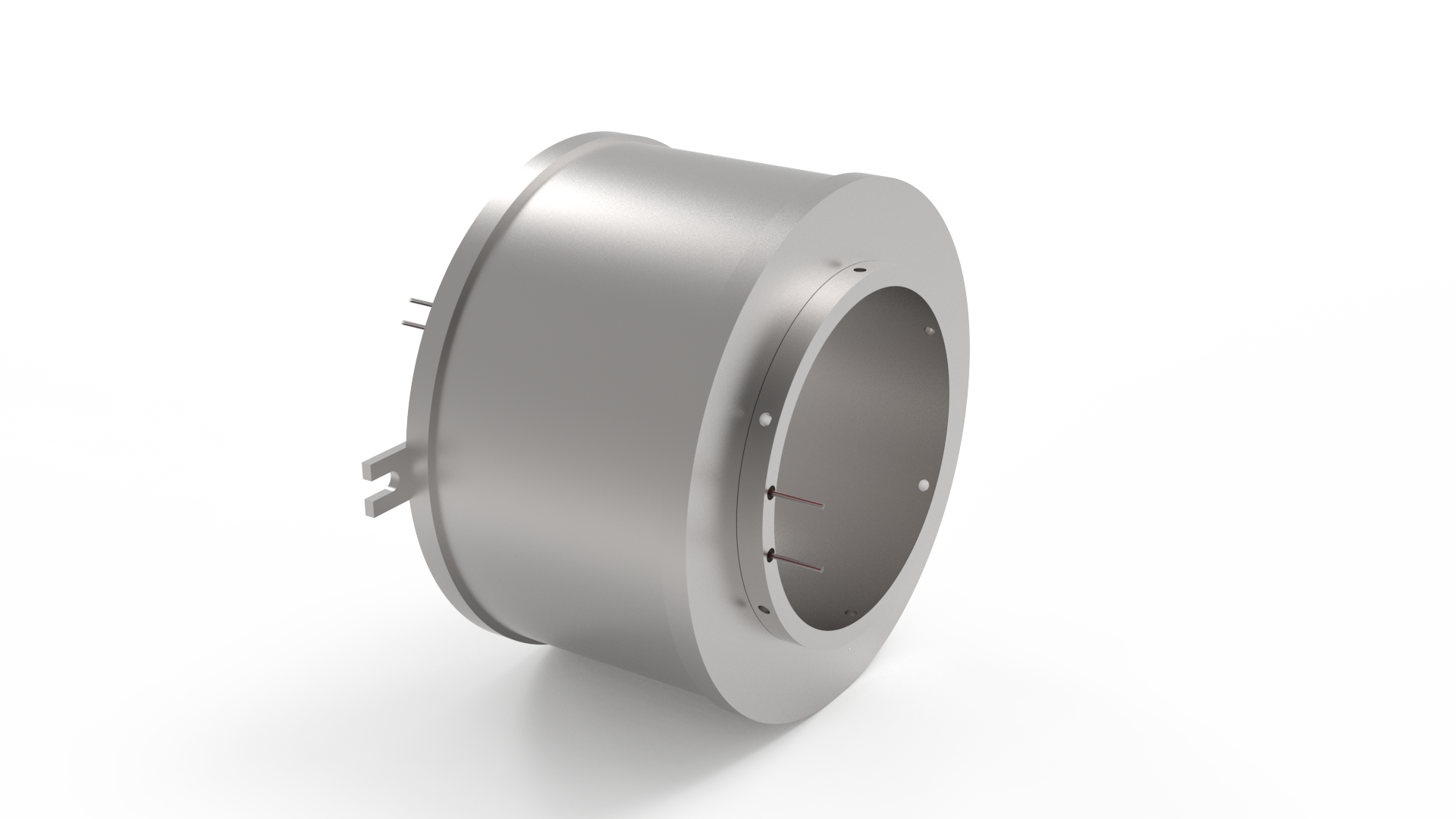

Aerospace test fixture. For this application, which required a more durable design, we customized one of our standard slip rings to include stainless steel housing, a 250-millimeter through-hole and custom wire gauge and lead length. We also extended the operating temperature range to 160ºC.

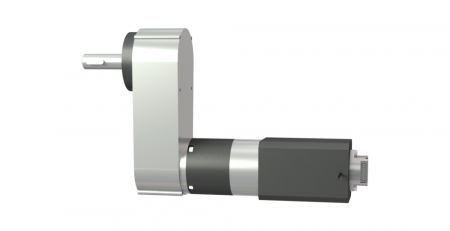

Pipe welding machine. To meet the requirements of a pipe welding machine, we modified the through-hole diameter and length of one of our standard slip rings. We also added 12 power channels at 600 volts, 45 signal channels and a high-speed coaxial data channel.

Ready to get started? Our online tool makes it easy to configure your own slip ring. Simply select the form factor you need and enter your required power, signal and data circuit criteria, plus any dynamic requirements like speed, duty cycle and temperature range.